fureverywhere

beloved friend who will always be with us in spiri

- Location

- Northern NJ, USA

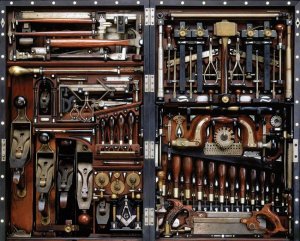

I need some suggestions for getting a moderate amount of rust off of several wrenches and screwdrivers. I have a good sized tool box that was on the front porch. It got knocked over and everything was haphazardly tossed back in. I just got it sorted today and noticed a lot of rust on some things.

I'm pretty handy with repairs and would like to clean everything up and get it organized. The farmers almanac says rub the rust with foil or soak in white vinegar. Any other helpful hints?

I'm pretty handy with repairs and would like to clean everything up and get it organized. The farmers almanac says rub the rust with foil or soak in white vinegar. Any other helpful hints?