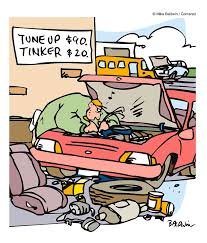

Years ago, American car makers were more concerned with output than quality. My buddies, who worked in Detroit, told me about cars rolloing on down the assembly line without all their bolts, because they were delivered in time to be installed. What ever was wrong - the dealership was supposed to fix. I think that industry wide era of shoddiness has passed. I have had a 2009 Hyundai you can't kill.

For many years, the really BIG dealers across the country would not accept what was referred to in the business as "Friday, Monday or World Series cars". Here's why:

On the factory floor, as the cars are pulled down the line, each worker has a certain area along the line in which to do his "job". Let's say Joe's job is to put four bolts in place to hold something vital in place, and tighten those bolts. He has a pneumatic bolt tightener in his hand with a hose that can stretch six feet in either direction. The second that car reaches the first place his tool can reach, he starts in working. He drops the bolt in and tightens it. He drops the second bolt in and tightens it. Same for bolt 2 and 3.

On most days, Joe can get that done before the car moves down the track and goes beyond where his tool can reach. Good. But say it's Friday afternoon and hunting season starts tomorrow and Joe can't get his mind off that big buck he's going to shoot this weekend. He's racking his brains to remember if he has enough ammo or will have to get to the store before it closes. Oops, he's run out of time before he got the 4th bolt in. OR, it's Monday and Joe has a killer hangover. He's moving a bit slow today and doesn't get that 4th bolt in. OR, the deciding game of the World Series is playing and Joe's listening on his little radio (because Joe's union negotiated the right for the line workers to have their radios there). Joe's distracted by the fact that his team is up to bat and down by two, it's the bottom of the ninth, bases are loaded, there are two outs, and the homerun king is walking up to bat. The pitcher throws, there's the crack of ash hitting leather, everybody's screaming. Does Joe have a lot of interest in whether that 4th bolt gets tightened? No, Joe does not.

So, the car hits the inspector, who notices that only three bolts have been installed. He has a dilemma. He needs to catch mistakes and stop the line so that the car can be fixed. BUT, if he catches *too* many mistakes, he won't have that nice inspector's salary for much longer as it costs an astronomical amount in lost productivity every time the line is stopped. He has the *unofficial* wink-wink-nod-nod to look the other direction a portion of the time.

Thus, that car goes out with only 3/4 of the amount of bolts that the automotive engineers feel is optimal to hold that important part in place.

And THAT, boys and girls, is why you don't want a "Friday, Monday or World Series car".